EVENT DETAILS

Abstract:

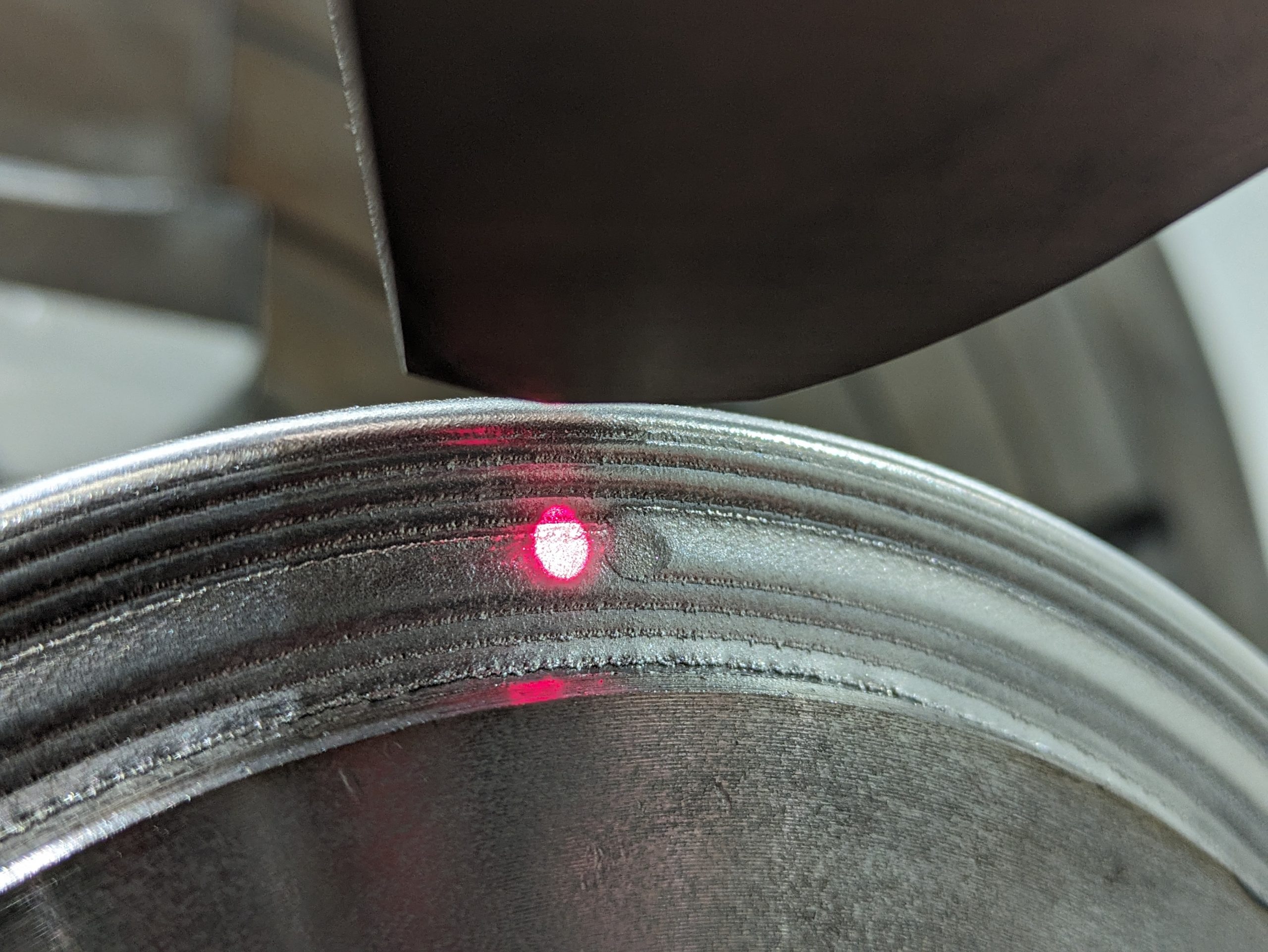

Ferrous components compose the majority of industrial machinery assemblies. The wear of these components leads to substantial waste streams that can be mitigated by refurbishment operations. By levering modern laser sources, laser cladding technologies improve refurbishment offerings over those of traditional repair processes like arc welding. With the aim of producing generalised lessons to enable wider ranges of repair for ferrous components, the presentation reviews the PhD candidate’s research and development investigations into two related laser cladding processes, five ferrous substrate types, and four cladding alloys. The evolution of heat affected zones in multi-phase substrates are discussed with reference to dimensions of inherited microstructures and the process type. The generation of porosity in grey cast irons is discussed with respect to process parameters outside of the standard power-speed-feed paradigm, and alloy hardnesses are correlated with controllable dilution levels. A nickel-rich high entropy alloy produced on ductile cast iron is discussed, with a controlled microstructure transition from dendritic to lamellar grains yielding improved mechanical properties. Finally, the recycling of martensitic stainless steel powders is discussed, with recycled powders displaying increased deposition efficiencies and altered grain structures. The wear performance of recycled claddings is assessed, and the viability of the powder recycling processes is discussed. A holistic assessment is made regarding learnings related to laser cladding, alloy design, processing, and research and development.

Bio:

Hank Lloyd is engineering graduate from the University of Auckland, New Zealand/Aotearoa. He holds a Chemicals and Materials Engineering BE Honours and a Research Masters degree, both with distinction. Involved in foundry work from a young age, he has a special interest in metals and other crystals. His honours project, on the plasma spray of the bioceramic hydroxyapatite for mussel habitat regeneration, provided a hands-on introduction to materials processing and characterization. His PhD thesis is focused on laser cladding for the repair of ferrous components, and is performed with the ARC SEAM training centre at the Swinburne University of Technology node in collaboration with the industrial partner D&T Hydraulics and Engineering, Mackay. The PhD opportunity has allowed him to pursue his interest in metals, their formation, and their use.

Outside of the research environment, Hank enjoys programming, design, and volunteering. He has been fortunate to encounter leadership roles at the Connected Community Hackerspace, Melbourne, where he is currently in a second term as “el Presidente”.

PRESENTED BY:

Hank Lloyd

DATE

13 March 2025

TIME

11:00 am - 12:30 pm (GMT+11)

Convert to Local Time

LOCATION

EN313, EN Building, Swinburne University of Technology, Hawthorn Room: EN313 Level 3, EN Building

Serpells Lane, Hawthorn