EVENT DETAILS

Come and celebrate the completion of SEAM HDR Alexandre Ugwechi Osi’s thesis submission.

Abstract:

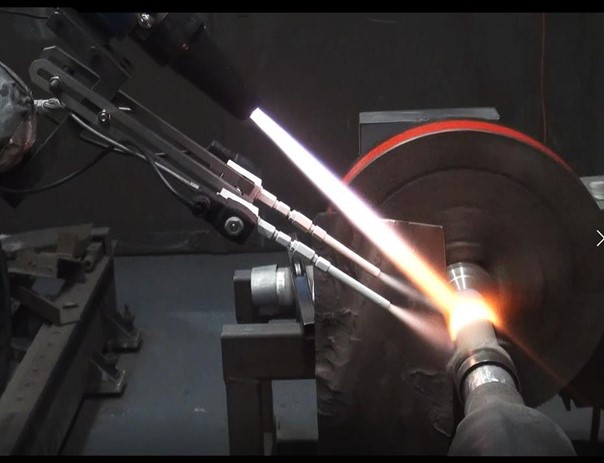

The manufacturing industries operating within the marine, aerospace, renewable energy, and automotive sectors increasingly recognise the need to optimise their operational performance, product integrity, and manufacturing costs. This has led to a growing demand for materials offering a high strength-to-weight ratio and improved mechanical strength while maintaining structural stability. In marine applications specifically, engineering materials encounter several in-service challenges because they are constantly in contact with an environment dominated, mainly by alkaline seawater moisture and a three-dimensional high-stress impact of sea pressure and waves. Standard metals and alloys often suffer from environmental-induced degradation, causing corrosion, biofouling, wear, and material fatigue. These issues significantly reduce the mechanical integrity and operational performance of these materials. Thus, there is a pressing need for advanced materials to effectively mitigate these issues and improve the overall performance and durability of marine equipment and structures. Polymer matrix composites (PMCs) are the frontier of this innovation. Thermal spray coating has shown the ability to enhance corrosion and wear resistance, improve structural/mechanical properties, provide thermal insulation, and improve part service life of various structures and components.

This research project has successfully designed, modelled, manufactured, assembled, and tested a functional PMC hydraulic cylinder piston rod prototype that is thermal spray coated with WC-10Ni-5Cr (-30 + 5 µm) material up to a stage six technology readiness level. The prototype has a substantial weight reduction (up to 80%) compared to conventional nickel aluminium bronze alloy piston rods. The weight reduction achieved in the hydraulic piston rod has immediate implications for industries where weight is critical, such as aerospace, automotive, and marine applications. This novelty can lead to substantial weight reduction, which has several advantages, including increased efficiency, reduced fuel consumption, increased payload capacity, and overall operational performance. Furthermore, the design of a hydraulic cylinder that is lightweight and can be easily maintained or the piston rod easily refurbished is very important for the future of hydraulic cylinder manufacturing. This approach aligns with the evolving demands of hydraulic cylinder manufacturing, promoting efficiency, sustainability, and longevity in various applications. This research also provides valuable insights into determining the optimal cooling conditions for applying thermal spray coatings onto temperature-sensitive substrates like PMC. Furthermore, this research provides an in-depth understanding of the relationship between cooling media, heat flux transfer, and the time between passes, which offers a comprehensive perspective on achieving high-quality coatings while preserving heat-sensitive substrate integrity.

About the speaker:

Alexander Ugwechi Osi holds a double Bachelor of Engineering degree in metallurgical engineering and material science from the Federal University of Technology, Owerri, achieving distinction in both fields. He furthered his academic journey by completing a Master of Engineering (Manufacturing Engineering) at RMIT University, also graduating with distinction. Alexander’s fascination with materials science and metallurgical engineering began during his teenage years when he witnessed a tragic incident in which a newly constructed building collapsed on his street, resulting in casualties and injuries due to material failure and poor engineering practices. This event, among others, stimulated his curiosity for engineering materials and understanding material failures. Driven by a growing passion for understanding the root causes of material failures, he pursued formal education in the field. Alexander is a registered professional engineer by both Engineers Australia (MIEAust) and the Australian Professional Engineers Association (APEA).

PRESENTED BY:

Alexander Ugwechi Osi

DATE

22 July 2024

TIME

12:00 pm - 2:00 pm (GMT+11)

Convert to Local Time

LOCATION

TD144, TD Building, SUT Hawthorn Campus | https://swinburne.zoom.us/j/86714617526 Room: TD 144, Level 1, TD Building or online: https://swinburne.zoom.us/j/86714617526

1 John Street, Hawthorn