EVENT DETAILS

SEAM Webinar

‘Development of Cold Sprayed Coatings for Biomedical Applications’

Prof. Harpreet Singh (Indian Institute of Technology Ropar, Rupnagar, India)

Chair: Dr. Surinder Singh (Postdoctoral Research Fellow, SEAM, Swinburne University of Technology)

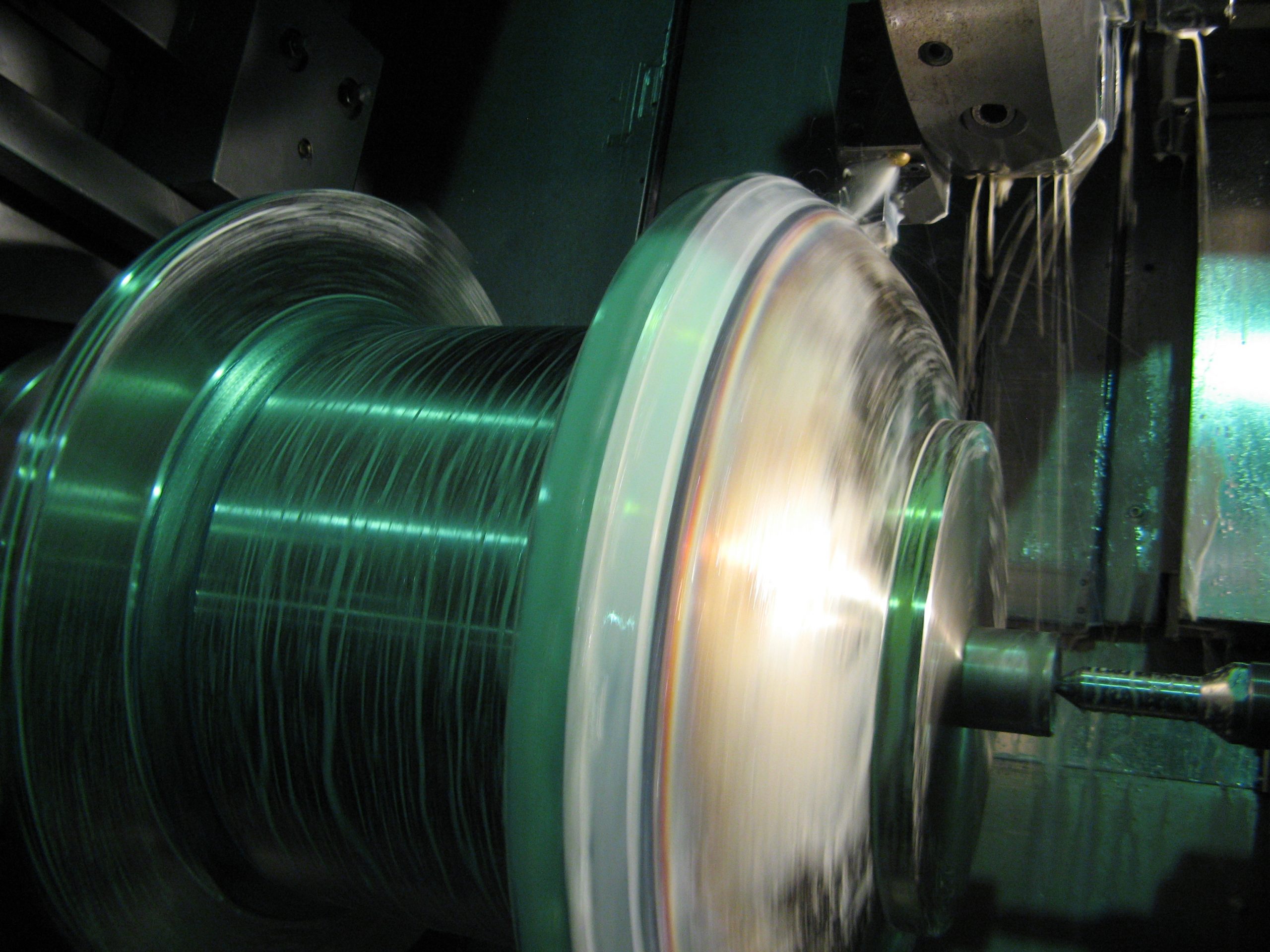

Prof Singh will present a research work on the surface preparation requirement for cold-sprayed Ti-based coatings on SS316L biomedical steel. A case study related to development of cold spray Ti-based (Ti/TiO2 and Ti/BAG) coatings for bio-implant surfaces is presented. The deposited coatings are subjected to microstructural and mechanical characterization using advanced characterization techniques. Electrochemical corrosion and sliding wear response of the deposited coatings are evaluated and discussed in detail. Moreover, laser treatment of the deposited coatings is performed with an aim to enhance the corrosion and wear performance of the coated steel.

Prof Harpreet Singh currently working as a Professor in Mechanical Engineering at Indian Institute of Technology Ropar (INDIA). He did his PhD from Indian Institute of Technology Roorkee in 2005. During his PhD, he worked on high temperature corrosion of superalloys and its prevention by plasma spray coatings. He has been doing extensive research work in several areas related to surface engineering and manufacturing since the year of 2002. He is a recipient of “Kansai Nerolac Excellence Award for the Excellence in Coating Research”, “Young Scientist Award”, “Career Award for Young Teachers (CAYT)” and “Maharashtra State National Award for the Research Work done by the Teachers of Engineering Colleges-2007” by Society for Surface Protective Coatings (India), Punjab Academy of Sciences, AICTE and ISTE respectively.

The orthopaedic implant market is growing exponentially. The life of orthopaedic bio-implants is expected to be up to 15-20 years, depending upon various factors such as gender, age, and patient’s body mass index. Corrosion and wear contribute significantly to the degradation of bio-implants in the body environments. Released ions and worn-out material (wear debris) leave toxic effects on the human body and promote several diseases such as Alzheimer’s and Neuropathy. Surface modification is one of the popular routes to achieve the desired response from bio-implant surfaces. Thermal spray (plasma spray) is approved as a surface modification technique for bio-implant surface modification by Food and Drug Administration (FDA) USA. However, high processing temperature in thermal spray limits its use for heat-sensitive biomaterials. In this context, cold spray is getting attention to efficiently deposit micron-sized metallic and non-metallic heat- and oxygen-sensitive biomaterials on bio-implant surfaces due to its low processing temperature. A plenty of research work has been published on the deposition of hydroxyapatite (HA) coatings using the cold spray. Recently, a promising alternative to HA, that is, Baghdadite (BAG) is considered owing to its attractive mechanical, chemical, and biological properties.

Event contact: seam@swinburne.edu.au

PRESENTED BY:

Professor Harpreet Singh (Indian Institute of Technology Ropar, India)

DATE

07 December 2022

TIME

3:30 pm - 4:30 pm (GMT+10)

Convert to Local Time