EVENT DETAILS

SEAM Webinar

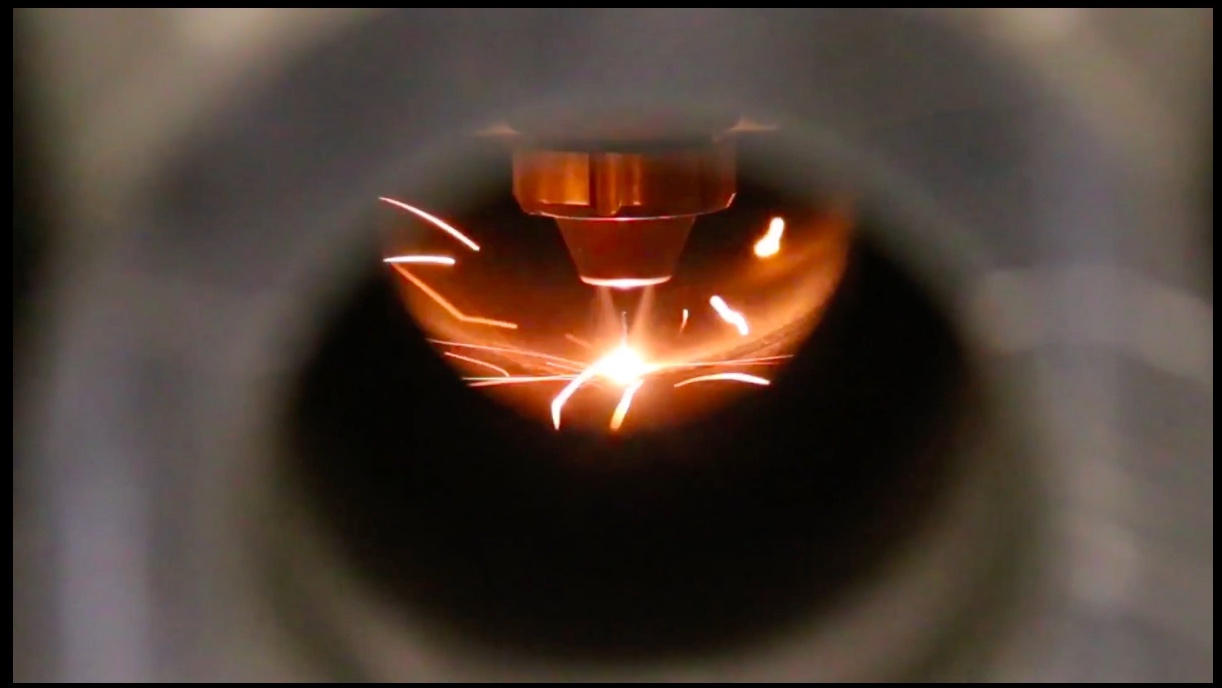

Laser metal deposition (LMD) process parameters and defect detection

Presenters: Dr Patrick O’Toole (RMIT University) and Dr Anthony Roccisano (University of South Australia)

Moderator: Dr Christiane Schulz (University of South Australia)

Click on the image to watch the presentation.

Laser metal deposition (LMD) is an advanced manufacturing technique that can provide solutions for additive manufacturing, repair, and product improvement for a variety of industries such as mining, agriculture, and defence. Products produced for these industries are often subject to extremes in temperature, wear, and corrosion, necessitating high reliability and minimal internal defects. As systems and processes mature, the likelihood of defect formation decreases, however, the risk of critical defects that threaten the integrity of the part necessitate postproduction inspection. We explore newly developed techniques that have the capability to detect defects as they occur during manufacturing, enabling problems to be remedied as they occur. Optimising the process parameters can significantly improve the reliability of the process, however, testing all possible process parameters is a time consuming and costly endeavour. Using computer modelling, process parameter combinations are evaluated prior to conducting experimental testing, reducing cost and time of build optimization. The rapid maturation of the LMD process aided by computer modelling combined with online defect detection may greatly reduce production costs and losses due to defect formation and premature failure.

Dr Anthony Roccisano is a Postdoctoral Fellow with SEAM, with the University of South Australia node. His research strengths include materials characterization, electrochemical analysis, and mechanical design. Anthony’s research interests include: Laser Metal Deposition (LMD) for wear and corrosion resistance; and LMD process optimization and control. Anthony completed a Bachelor of Mechanical and Aerospace engineering (2015) from the University of Adelaide and received his PhD (also Adelaide) in 2020 from the school of mechanical engineering on his research entitled ‘Manufacturing processes leading to improved high pH SCC resistance in pipes’.

Dr Patrick O’Toole joined SEAM and RMIT as a Research Fellow in 2021 to develop a model of laser metal deposition and apply it to high-speed laser cladding, and to develop a model integration to predict hot cracking in 3D printed parts. Prior to SEAM Patrick worked at CSIRO, where he developed a multiscale model of solidification of Al-Si alloys. This model is currently being used to generate training data for machine learning methods to improve part-scale simulation with accurate solidification characteristics. Patrick has worked at The University of Melbourne in collaboration with UNSW Engineering and DST Group maritime research to develop scale-bridging microstructure and crystal plasticity methods. Patrick holds a bachelor’s degree with first-class honours in chemistry from The University of Sydney. He obtained his PhD, from the Universities of Sydney and Venice, specializing in computational chemistry, mesoscale particle simulation, and free-energy methods.

PRESENTED BY:

Dr Patrick O’Toole (RMIT University) and Dr Anthony Roccisano (University of South Australia)

DATE

14 October 2021