EVENT DETAILS

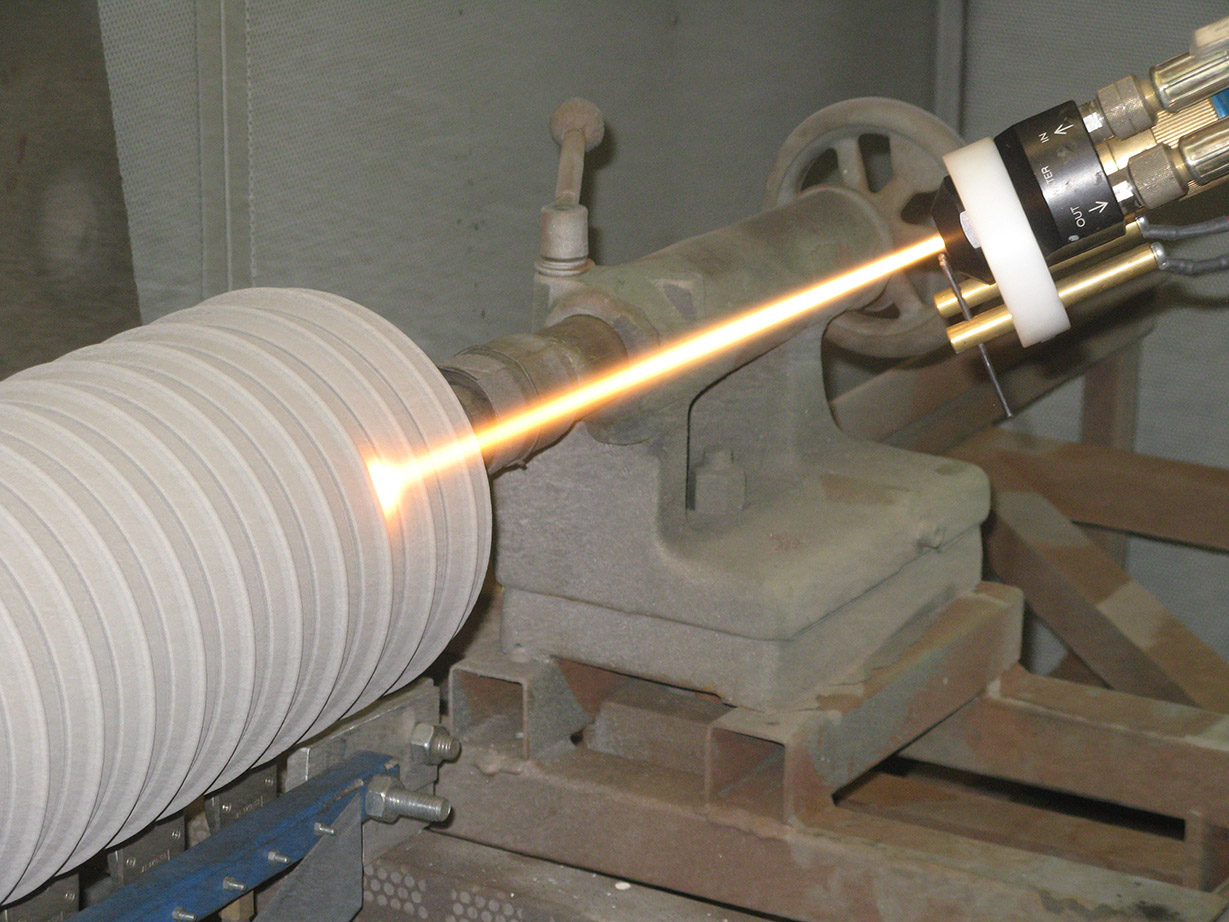

In this SEAM seminar Mr Abbas presented how high-velocity oxy-fuel (HVOF) deposition is a thermal spray process which uses high kinetic energy to produce coatings of high strength and density. Single splat formation is fundamental to define the structural integrity of the entire coating structure. However, limited understanding is available with respect to splat formation behaviour and splat-substrate interface properties of HVOF coatings because of the difficulties involved in the high-resolution characterisation of these features. In the present study, Ni powder was sprayed onto both mild and stainless-steel substrates using HVOF deposition to comparatively analyse the effect of substrate surface properties on splat formation.

A range of microscopy techniques including scanning electron microscopy (SEM), focused ion beam (FIB) microscopy, transmission electron microscopy (TEM), scanning transmission electron microscopy (STEM) and energy dispersive X-ray spectroscopy (EDX) were employed to characterise both splat morphologies including their cross-sectional structure, as well the nature of the splat-substrate interface. It was shown that the majority of the particles reached the substrate surface in a partially melted form owing to the high velocities typical of the HVOF process. Mr Abbas explained that the splats produced on the mild steel substrate displayed comparatively less splashing as compared to the splats formed on the stainless-steel substrate. Ni-Fe interdiffusion profiles, determined by STEM-EDX linescans, revealed significant diffusion at the splat-substrate interface, especially in the case of the stainless-steel substrate. These microstructural observations are correlated with the thermo-mechanical characteristics of the substrates to provide a model for the mechanisms driving splat formation.

Musharaf Abbas is a PhD Candidate with the School of Material Science & Engineering at UNSW with Professor Peter Munroe (UNSW) as his primary supervisor, with main research areas of thermal spray coatings and material characterisations. Musharaf received a Bachelor of Science in metallurgical and materials engineering (University of Engineering and Technology, Lahore) followed by a masters in materials science and engineering (Beijing University of Aeronautics & Astronautics).

PRESENTED BY:

Mr Musharaf Abbas (UNSW)

DATE

06 November 2019